When process engineers need to separate, clarify, or fractionate process streams—and where they demand reliable and repeatable performance—membrane filtration systems are more frequently becoming their first choice.

At its most basic level, membrane filtration involves separating a single flow into two streams, one more concentrated than the other, by using pressure to selectively pass material through a semi-permeable physical barrier—a membrane. The separate streams can then either undergo further processing, or, in the case of a waste stream, be diverted to an appropriate outlet.

With the ability to separate particulates from the dissolved species and separating dissolved species themselves, a membrane system can be used to produce a more concentrated or purified end-product. With the correct membrane selection, the filtration process can isolate dissolved species of specific sizes while allowing other dissolved components to permeate through the membrane.

One of the main deciding factors used in choosing the proper membrane is the nature of the process fluid. Knowing the dissolved-solids content, the molecular weight of the dissolved species, and the nature and loading of any suspended material will direct the engineer towards the correct membrane selection and geometry. The pH and temperature of the incoming process stream are also important factors in making the final decision.

Filtration for all Molecular Weights

The membrane filtration spectrum starts at the smallest molecular level with reverse osmosis (RO), a process that allows the finest degree of separation. More dissolved species will pass through a membrane as you move through the filtration range from dewatering or water purification with very ‘tight’ reverse osmosis, through nanofiltration, ultrafiltration, and finally microfiltration which is essentially a separation of submicron particulates from dissolved material.. Between them, these processes can separate particles that differ in size by anything from a few angstroms up to a few microns. The various levels of membrane filtration require internal pressures ranging from 1000 psi (70 bar) in high-pressure systems, down to under 15 psi (1 bar) in low-pressure microfiltration units.

The membrane filtration spectrum ranges from reverse osmosis (RO), which allows the finest degree of separation, through through nanofiltration, ultrafiltration, and finally microfiltration, which separates submicron particulates from dissolved material.

RO uses a tight membrane that retains almost all dissolved species including sugars and salts. The pressure in this system must exceed the natural osmotic pressure of the dissolved water or other solvent across the semi-permeable membrane. RO systems are particularly useful in concentrating low concentration fruit juices, tea, coffee, and sugar solutions, and the technology is also often used for concentrating wastewater-effluent streams such as landfill leachate.

Nanofiltration, the next level of filtration, bridges the gap between RO and ultrafiltration. It’s often used for desalting liquid dyes or concentrating antibiotics. Ultrafiltration is used in a wide range of industrial applications, as its versatile nature lends itself to separating flows as diverse as effluent streams from dye-houses and pulp and paper mills, protein concentration in the dairy industry to juice clarification. It can also be used as a pre-treatment to avoid particulate fouling of resin columns,

The higher end of the particle-size spectrum requires microfiltration. Here, ceramic and polymeric membranes are often used to provide a wide range of pore sizes for processing liquids in the food, beverage, pharmaceutical, and chemical industries, as well as for separating wastewater effluents.

Membrane Configurations and Materials

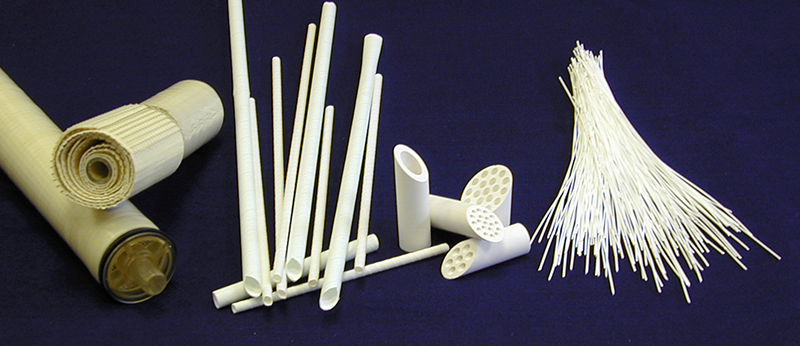

Membrane filtration technology has developed both in the way membranes are packaged and in the type of membrane material used. The result is a wide range of module configurations and membrane geometries, which are suited to a variety of applications. Membranes are normally supplied in tubular, spiral, flat-sheet, or hollow-fiber arrangements with other more recent novel configurations that induce vibration or use rotating vanes to increase filtration rates by reducing membrane surface concentration polarization effects (These novel approaches are not always economical however).

Membrane configurations (left to right) include: spiral wound, polymeric tubular, ceramic tubular and hollow fiber.

Tubular membranes, for example, have several advantages. They can handle viscous liquids with high levels of suspended solids and can be chemically or mechanically cleaned. Tubular polymeric membranes are typically housed in modules of stainless steel or plastic.

Spiral membranes, as the name suggests, consist of tightly packed filter material sandwiched between mesh spacers and wrapped in a small-diameter tube. This high packing density means there is significantly more surface area in a given filtration unit than can be provided by tubular membranes. If suspended solids are present in the process stream, however, spiral membranes require careful pre-filtration to avoid blocking and clogging. Developments in mesh-spacer sizes and designs are helping to increase the number of applications for which spirals are suited.

Hollow Fiber membranes are also densely packed and consist of extruded fibers with a small hollow portion. Filtration can occur from inside the fiber to the outside or in the reverse direction from the outside of the fiber to the inside allowing for a backwash cycle. Although more resilient to small particulates than spirals, hollow fibers will also often require pre-filtration where larger particulates or fibers are present in the feed material. Most hollow fiber membranes cannot be used at pressures above 30 psi (2 bar) without breaking.

Membrane materials are typically polymer- or ceramic-based. Polymeric spiral membranes are generally used when a high throughput is required, while polymeric tubular membranes, which can often be mechanically cleaned, are more suited for low-maintenance operations, highly viscous products, or fluids with suspended material.

Hostile environments, high levels of solvents, wide pH ranges, and other process considerations may dictate the use of ceramic membranes. This technology, normally adopted for ultrafiltration and microfiltration applications, typically uses an alumina or zirconia coating that is applied to the inside surface of a ceramic support. The capital cost of ceramic membranes is much higher than with conventional polymeric membranes, but in some applications they are the only viable proposition. Offsetting the high initial cost, though, is the fact that ceramic membranes often provide a longer operational lifetime. Ceramics are not resistant to abrasion however although polymerics may be.

Call in a Specialist

Choosing the right membrane for each application is vital, and firms experienced in membrane filtration (like Membrane Specialists, for instance) can help engineers make the right decision. For many applications, these companies can provide membrane filtration units as a standard design, requiring minimal testing. In other situations, design engineers may need to extensively test the process on-site. In these situations, experts like those at Membrane Specialists can be especially helpful because they’ve gained the experience and in-house expertise to provide solutions for filtration problems across a wide variety of industrial sectors and work with prospective clients to design and optimize a membrane filtration solution.

Before having a specialist determine the right membrane system for the application, it’s important to do some preliminary financial assessments to see if installing such a filtration plant can be a viable proposition. Accordingly, some design criteria must be identified, such as:

- the capacity of the plant;

- the operating costs; and

- the nature and desired composition of the “permeate” (the liquid fraction passing through the membrane) and “retentate” (the concentrated fraction retained by the membrane).

Typically, Membrane Specialists will help define the design criteria by conducting a short pilot trial on site or in its own laboratory using a sample of the process stream, to narrow down the choice of membranes.

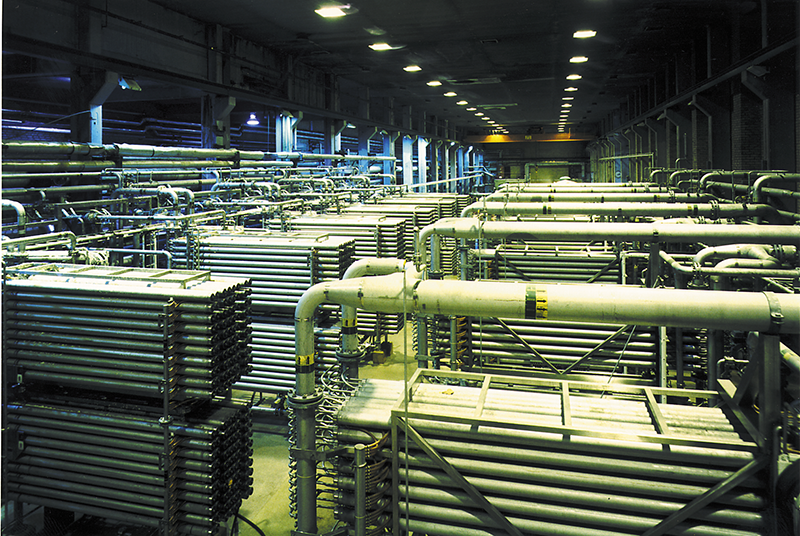

Pilot plants like this one allow engineers to evaluate different membranes and realistically test for membrane fouling, permeation rate, pressure drop, retention levels, cleaning regime effectiveness, and quality of the end product.

Then a test rig or pilot plant is set up at the factory site. This will test the effectiveness of the chosen membrane system on a larger scale, utilizing up to 161.45ft2 (15 m2) of total membrane area. In the initial trials, it’s important to collect as much useful data as possible because the final design parameters will be based on this information. It’s also important to answer the following questions: Will the system be used on a batch or continuous basis? How long can the plant be taken off-line for cleaning? What are the key criteria for judging success? These initial trials typically last for 2-3 weeks but can take longer if the process fluid varies in composition or volume over time. A well-designed testing procedure will save time and effort later.

With the test rig, engineers can take realistic measurements, including the degree of membrane fouling, the permeation rate (“flux”), the pressure drop, the retention levels as concentration increases, the effectiveness of the cleaning regime, and the quality of the end product. From these data, the final system design is developed. In cases where a standard membrane is not suitable for the application in question, a new configuration of the membrane system may be needed. Also at this pilot stage, Membrane Specialists design engineers can estimate the probable membrane life span, and this can be taken into account when considering the total lifetime costs of the system.

Membrane Specialists LLC takes an unbiased approach to crossflow membrane selection, ensuring truly independent solution, ideal for each application. Membrane Specialists offers the full range of membrane geometries, incuding spiral wound, hollow fiber and both ceramic and polymeric tubular membranes. This choice of configurations makes it possible to test across the entire filtration spectrum from reverse osmosis, through nanofiltration and ultrafiltration to microfiltration. Trials can be carried out in Membrane Specialists laboratories or at your site, with or without assistance.

Spotlight On

A Swedish paper mill wanted to attain the “Swan Mark,” a sign of environmental excellence. To do so, it needed to reduce the COD (chemical oxygen demand) in its bleach effluent by 50%. Initial membrane trials, showed excessive clogging of the membrane from the wood-pulp fibers. A series of evaluations on several different types of new membranes were conducted and the final configuration was ready for testing within two months. The large ultrafiltration plant pictured above was ultimately installed and continues to effectively reduce the paper mill’s COD releases without any problems.