Membrane Filtration Plants

Membrane filtration plants can be designed using a variety of membrane configurations, each with unique characteristics to suit a wide range of process requirements.

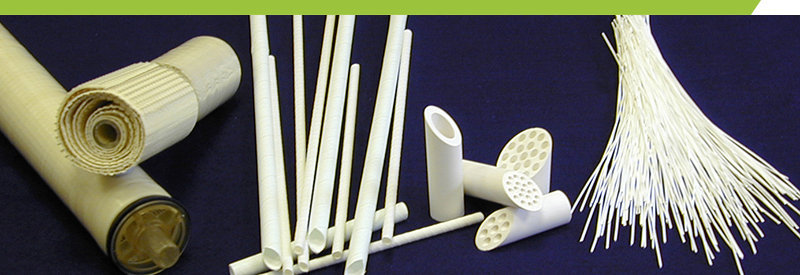

Spiral Wound

This compact membrane format can be operated at high pressures, and with suitable spacer materials, can accept high-viscosity feeds. (left in photo)

Tubular

Intended for high solids or large suspended solids, tubular membranes can have internal diameters (ID) ranging from ¼ to ½ inch (6.35 – 12.7 mm). They may be made from polymeric or ceramic materials. (center in photo)

Hollow Fiber

Hollow fibers range from .019 to 0.118 inch (0.5 to 3 mm) ID and make it possible for a large surface area to be housed in a small volume. (sidebar photo)

Modules and Housings

Membrane modules and housings include an outer shroud—commonly stainless steel or fiberglass—that surrounds and protects the membranes, while retaining the permeate and directing it to the intended transfer point. All have been carefully designed to achieve the maximum membrane surface area. They allow optimum operating parameters, such as crossflow velocity, pressure and temperature to be established ensuring optimum membrane performance.

Membrane modules and housings include an outer shroud—commonly stainless steel or fiberglass—that surrounds and protects the membranes, while retaining the permeate and directing it to the intended transfer point. All have been carefully designed to achieve the maximum membrane surface area. They allow optimum operating parameters, such as crossflow velocity, pressure and temperature to be established ensuring optimum membrane performance.

For more information on PCI Membranes, visit www.pcimembranes.com