Membrane Filtration

Crossflow membrane filtration is now a mature technology, regularly employed as a standard technique for liquid processing to effect clarification, product isolation, concentration and/or separation in a large number of manufacturing industries. Benefits of this technology include:

- Selective and consistent separation

- Increased product yield

- Low energy consumption

- Small footprint

- Established technology

- No additives, flocculating agents or pre-coat chemicals required

- Large variations in feed quality have little influence on permeate quality

- Easy retrofitting

- Low maintenance

Basic Principles

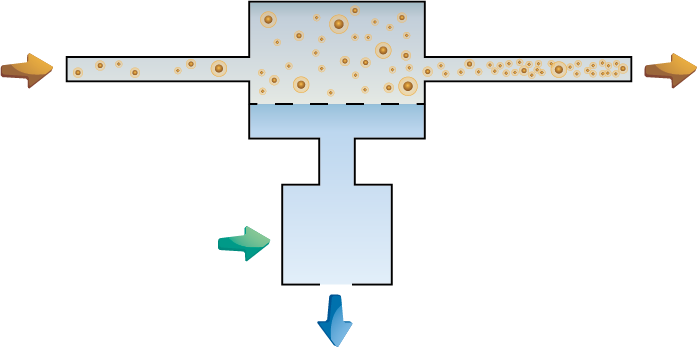

In conventional filtration the feed flow is perpendicular to the membrane surface, which causes a buildup of debris that eventually reduces fluid permeation. In crossflow filtration, flow is tangential to the membrane surface resulting in a continuous scouring action that almost eliminates formation of a membrane fouling layer from feed-stream debris and macro molecules. Driven by pressure in the filtration modules, part of the liquid passes through the membrane. This fraction is called “permeate” or “filtrate,” while the fraction that does not pass through the membrane is called the “retentate” or the “concentrate.” In some applications, the end product may be the permeate – as in fruit juice clarification or effluent purification – or the retentate, as in the concentration of antibiotics. In some cases, both streams – permeate and retentate – will be valuable end products. Depending on the size and type of the particles or solutes contained in the feed stream, there is a wide range of separation processes available.

For more detailed technical and application information, visit our Knowledge Center.

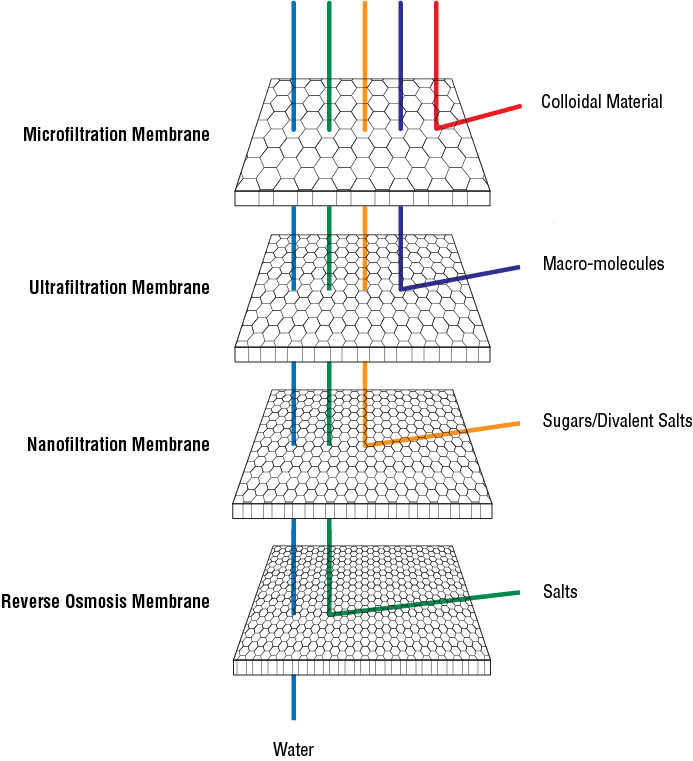

Microfiltration (MF)

A low-pressure process for the retention of suspended material particle size of 0.01 microns or large. Smaller particles (salts, sugars and proteins, for example) pass through the membrane. Typical operating pressures range from 5 to 45 psi (.34 – 3 bar).

Ultrafiltration (UF)

A medium-pressure process offering retention of proteins, colloids and biological material including particles 0.005 microns or larger (molecular weight greater than 1000 Dalton). Typical operating pressures range from 7 to 150 psi (.48 – 10 bar).

Nanofiltration (NF)

Water and monovalent ions, as well as low molecular weight substances (less than 250 Dalton) pass through nanofiltration membranes. Divalent or multivalent ions, such as divalent salts, are retained. Operating pressures between 120 and 600 psi (8 – 41 bar) are typical.

Reverse Osmosis (RO)

A high-pressure process that retains almost all particles and ionic species, while water and some organic molecules pass through. Substances with molecular weight above 50 Dalton are retained almost without exception. Operating pressures are typically between 300 and 850 psi (21 and 59 bar), but may exceed 1100 psi (76 bar) in some applications.